Enhanced Bioavailability

At Microsize, we know speed is of the utmost importance in drug development. Getting to the next milestone faster will be critical to your success. Enhancing dissolution and bioavailability of your drug candidate via micronization is your fastest pathway to success! Here’s why:

First-Choice Technology – Micronization is the fastest approach to improving bioavailability (BA). Speed, combined with economies of scale also make micronization the most cost effective solution throughout drug development and commercialization. The choice is clear:

No formulation additives required – Eliminating selection, optimization and evaluation workpaths.

Rapid process development – Feasibility assessments often completed in one day with minimal API required.

Streamlined analytical development – No need for development of complex (or novel) analytical methodologies typical with other BA enhancing technologies.

Accelerated Process Validation – Reduced number of critical processing parameters (CPPs) resulting in simplified feasibility, DOE studies & process validation.

Technology Advantages of Micronization

STREAMLINED REGULATORY PATHWAY

As the most established BA enhancing technology over the last several decades, micronization is well-known to regulators worldwide. 100’s of NDA approvals have been granted using micronization as the primary technology for BA enhancement. At Microsize, our facilities have been FDA inspected on numerous occasions with a stellar compliance record and cGMP systems. We also host numerous client audits each year ranging from small biotechs to the world’s largest global pharma companies.

READILY SCALABLE

Micronization is an infinitely scalable technology for BA enhancement which speeds process scale up. What makes Microsize different is that we are not just users of micronization equipment; we are pioneers in the design and manufacture of the micronization equipment that we use. Microsize has the equipment and capabilities to offer seamless scale up with mills ideal for R&D, clinical, and commercial volumes. Staying with one provider streamlines the product development cycle.

HIGH YIELDING

Micronization is generally a high yielding approach to BA enhancement. Our unique micronization technology affords clients much higher yields, and in drug development, when clients can be “API-starved”, our high yielding technology is critical to client success. These yields carry through clinical and commercial volumes. Small scale batch sizes as little as 1 gram can be run for feasibility and large scale batch sizes with 99% plus recoveries are routinely achieved.

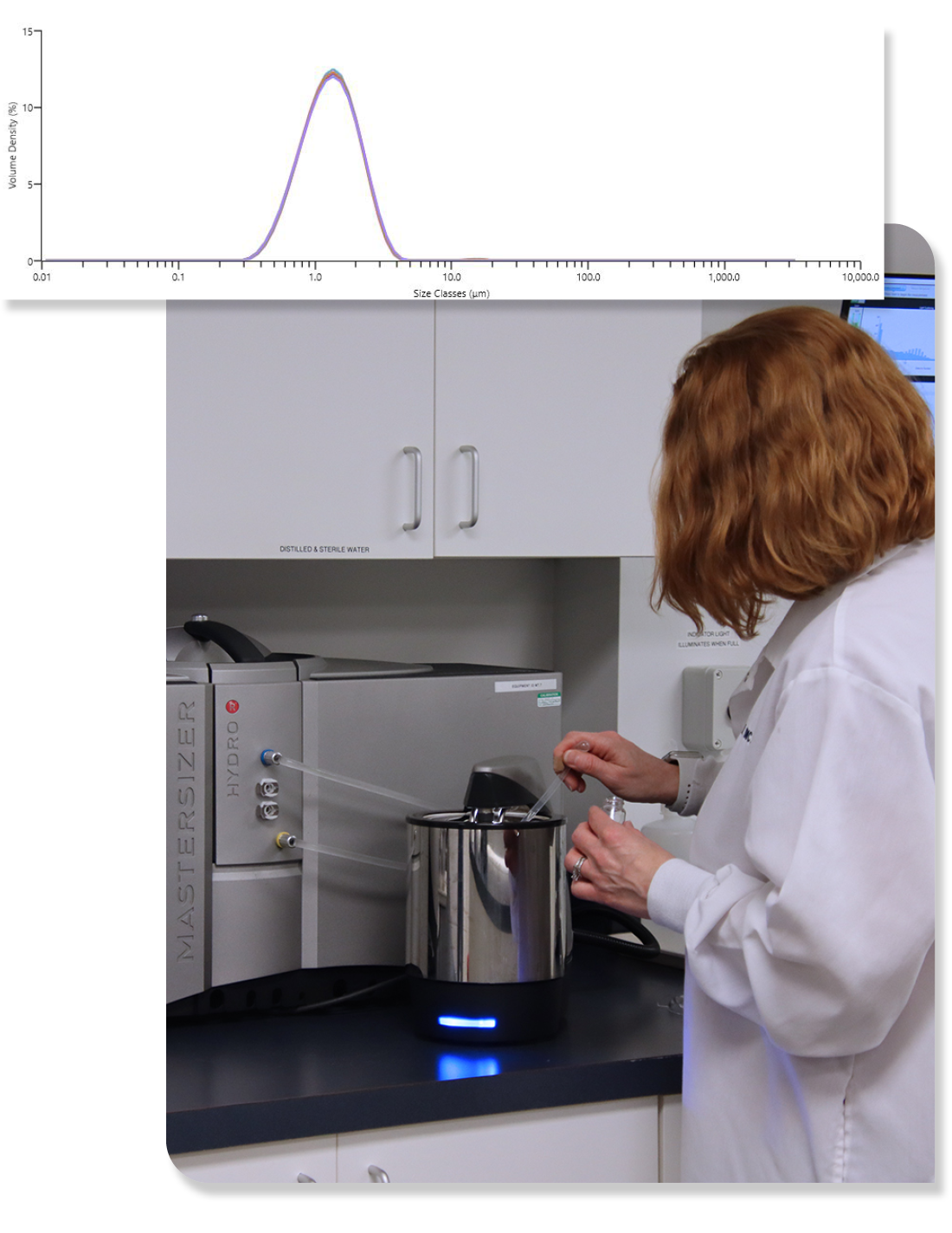

SUPERB PRECISION / REPRODUCIBILITY

Micronization provides a homogenous grinding environment, inherent to the micronization process, resulting in a narrow, fine and Guassian particle size distribution curve. Most API distributions can be micronized to under 10 microns, with average particle sizes in the low single digit micron range. These shape distributions (along with limited variables that have process influence), allow for excellent reproducibility. Typical commercial products run routinely at Microsize have ~1 micron variance around the median D50 value over 1000’s of batches, providing reliable product performance and unmatched consistency.